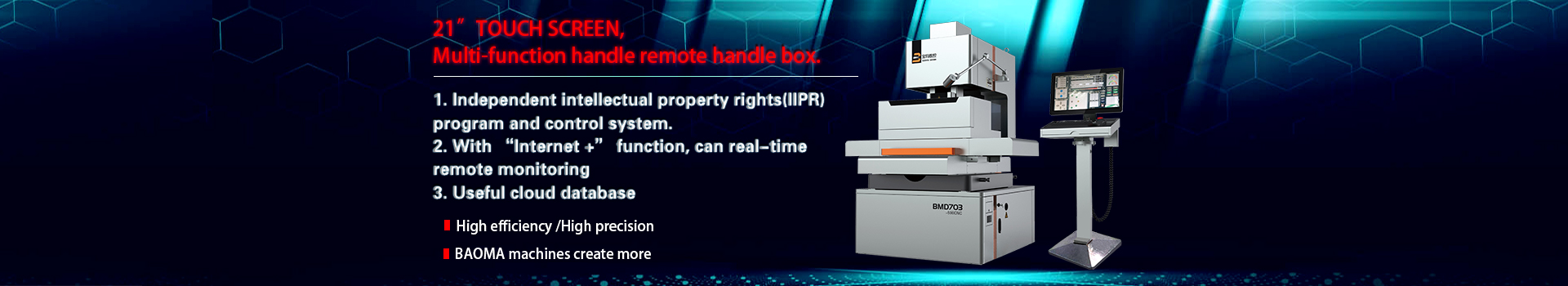

SPECIFICATION AND PARAMETERS

| Specification | BMD703-500 | Universal Parameter | |

| Work table Size | 410 x 590 mm | Drilling Depth | 0 - 300 mm |

| Work Table Travel | 400 x 500 mm | Z axis Travel | 300+(320) mm |

| Load of Table | 300 Kg | Max. Drilling Speed | 60 mm/min |

| Electrode Diameter | 0.2-3.0 mm | Max. Working Current | 30 A |

| Water Tank Capacity | 30 L | Max. Power comsumption | 3.5 KVA |

| Machine Weight | 700 Kg | Voltage | 220-415V / 50HZ |

| Machine Dimensions | 1379 x 1429 x 1886 mm | Working Solution | Water/Saponification |

| Packing Dimensions | 1680 x 1730 x 2050 mm | Function of setting depth | Yes |

| Control Type | ZNC: Z axis NC Control | Z axis Travel Control | Electric Motor |

High speed small hole drilling machine adopt electrode to drill hole according electrical discharge theory, put on high frequency Pulse electrical power between electrode and workpiece to create small pulse, cooperate with high pressure water plush to make more higher speed erosion, especially fit to drill hole diameter as 0.2mm-3.0mm on stainless, hardenedsteel, cooper, aluminum, and hardalloysteel, the depth-diameter ration can reach to 300:1. Be able to drill directly into bevel or curve surface.This machine is widely used to drill hole which used to be thread wire、and chemical fiber spinneret, spinneret hole of spinneret plate, filter plate, group holes of sieve plate、engine blade、heat dissipation hole of cylinder、the hydraulic、oil way of air operated valve、stomata. The machine can also erode the drill bit or taps broken in the working piece without destroy the original hole or screw.

CNC Small Hole Drilling Machine

1.Small Hole Drilling EDM Machine (BMD703-400) characteristics:

* Can drill deep hole with diameters 0.2mm ~ 3mm (the depth-diameter ratio is 300: 1)

* The speed of drilling hole is 30mm~60mm depth per minute (it is different for different material)

* Can drill wire-cut starting hole, filter hole, jet hole, gas hole, group holes and hole of super depth etc.

* Can drill small holes on the various conductive materials, even semiconductor material, especially stainless steel, chilled steel, copper, aluminium and hard alloy etc

* Can drill on oblique and curved surface directly

* Can easily erode the drill and screw tap etc which is broken in the workpiece and not destroy the screw thread of the holes

* The working water can be normal water or saponification fluid and no pollution is brought

* The operation is easy and convenient

* X, Y, Z axes have digital display devices

* Z axis has the function of setting depth

CNC Small Hole Drilling Machine

1.Main performance indexes and technical requirements.

2. Basic configuration:

A. Three axes have digital displays; It is consistent with operation

B. Z axis uses linear guide rail (driven by the step motor with 5 phases 10 beats), it is driven by DC motor

C. The rotary head is of straight gear transmission, its volume is small

D. The super large scales integrate circuits make the impulse power supply reliable

E. The multiple power supply of high and low voltage and high-power VMOS field -effect transistor

F. The double Z is moved by motor

G. The operate-control box is adjustable, it is fully considered to convenience of operator

H. It contains the operation and control mode of DD703

I. The specialty plunger pump, thread gap filter

J. The marble working table

K. The stainless fixtures

L. The accessories and consumable parts

M. The processing polarity can be changed

N. The processing stability is adjustable