Face to saponification short lifetime, bad environment, Baoma company employ famous professor to choose 800 ingredient to develop BM environment water base working fluid. All parameters exceed saponification, fit to country environment requirement, pass European ROHS chemical test, got SGS-CSTC European environment certification, got Patent for Invention (200710132380.4) and county high technical name. And our product are made as country county standard by authority department, fill the county blank in this field.

Baoma water base working fluid cover all CNC machining field, total 18 series, hundred kinds:

1. High finish/ high efficiency/economic/clean/environment wire cut working fluid

2. Lubrication and cool machine center working fluid

3. improve machining precise and down roughness grinder working fluid

4. prolong tools lifetime lathe working fluid

5. supper lubrication, rust prevention, cool milling machine working fluid

6. rust prevention

7. clean working fluid

Baoma BM series have good cost performance, improve machining efficiency, workpiece finish, machining environment, and down pollution. It bring a revolution from oil to water. Under pay more and more attention to environment condition, water base working fluid is direction, we export to European, USA some developed counties

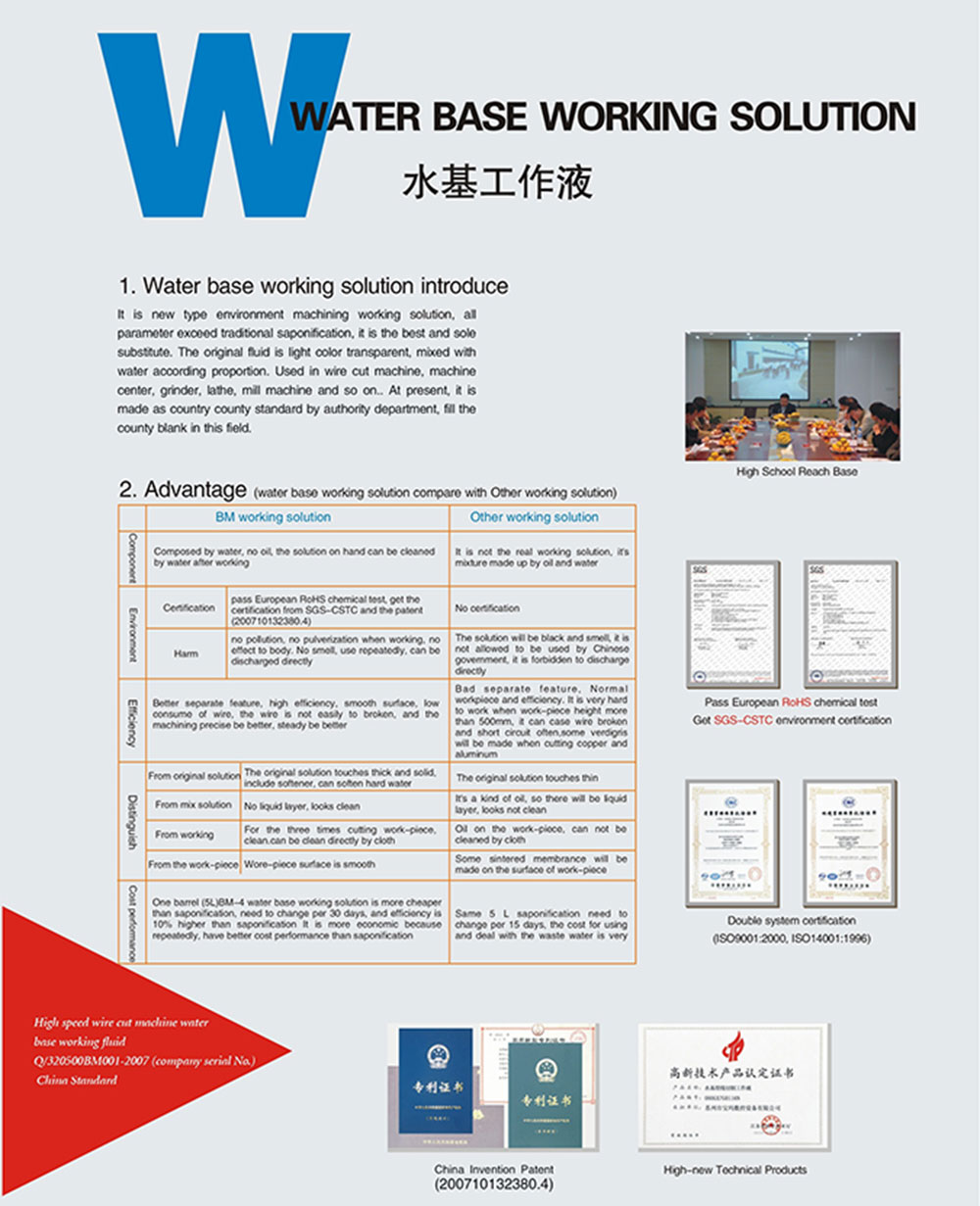

One. Water base working fluid introduce

It is new type environment machining working fluid, all parameter exceed traditional saponification, it is the best and sole substitute. The original fluid is light color transparent, mixed with water according proportion. Used in wire cut machine, machine center, grinder, lathe, mill machine and so on.. At present, it is made as country county standard by authority department, fill the county blank in this field.

BM series water base working solution compare with older saponification (Emulsified soap)

| BM water base working solution | Saponification(Emulsified soap) | |

| Environment | A. consist of water-soluble material can fix with tap water, no oil, no pollution, non-atomized water during working, no fetor, no bad influence to health. B. no oil pollution when working, clean and transparent. Reusable for a long time, down the cost, can be discharged directly, has been certificated by ISO14001 environment requirement, pass European ROHS chemical test and get the authorized certificate SGS-CSTC. | It is compose of Chemical Waste, which including some poisonous materials. It will cause pollution. It will be olid and back when working, harmful to body. Also it is bad to machine electrical part, and it is forbidden to discard directly in China. |

| Efficiency | Improve work piece finish, and efficiency is 20% higher than saponification, especially to big work piece it is more obvious. Because of better separate feature, the wire is not easily to broken, and the machining precise be better, steady be better Reduce the wear of the Moly-wire by around 10%. BM can be used for extra-thickness processing, which more than 500mm thickness. Regarding the using life of the machine, for the working solution is non-atomized, so there is no corrosion for the machine and the controller, which will prolong the life of the machine. | And the finish is not as good as the working solution and the surface is difficult to clear. Normal work piece and efficiency. It is very hard to work when work piece height more than 300mm. it can case wire broken and short-circuit often. It is easy to atomized, so there is corrosion for the machine and the controller, which will short the life of the machine. |

| Cost performance | We take BM-4 as a sample, One barrel (5L)BM-4 water base working fluid the mixture rate ( solution : water is 1:25), the price is USD27/barrel.The capacity for the tank is around 100L, The working solution can be used for much longer time than the saponification. 1-2 month change once for the tanker. For one machine it will cost USD10-15 per month if you use this kind of working solution. The guarantee for the working solution is one year. | One piece of saponification is around 1.5KG. The price is USD9/piece ( the price will increase for price petroleum price will go higher).For one tank you have to put 2-3 pieces per month, which cost around USD18-27/month.If there is any environment protection rules in your country, you have to pay for deal with the discard water. The quality is influenced by the environment, such as temperature. If in your country the temperature is higher than 25degree, the saponification is easy to go bad. |

Besides, we used the multi-filter tank for our machine, if you use the saponification, it will always cause the stoppage for the filter and influence your producing. But the new working solution will do better performance for the new design filter tank. So we can get conclusion from above, the new water base working solution have many advantages on Environment protection, Cost performance, efficiency, finish compare with the saponification. What’s more, the working solution is the trendy of this field, it have a good future and huge potential market. It must replace the saponification in the future.

Photos of working solution

Photo of saponification/Emulsified soap

None

None

None

None